About the sole of the eloxal iron, Braun can explain in detail. It was this manufacturer who produced a lightweight aluminum surface, which, after oxidation with electrolyte, gets high strength and a long service life even at high temperatures.

When buying an iron, not many users pay attention to the quality of the material of which the plate is made. In fact, this criterion is very important, since the sole of the iron is in direct contact with the surface that needs to be ironed. The difference in materials and the number of additional functions is quite large and varied. The pricing policy of the device also depends on the quality of these basic parameters.

Content

What are the varieties of the surface of irons?

Before proceeding to a detailed description of the capabilities of eloxal, it is necessary to consider in detail the types, types and differences of other soles for irons.

The main criterion for the sole of the iron is the material from which it is made. Now there are 4 main types of material:

- Ceramics. Irons with ceramic or cermet plates are very popular and in demand, since their cost is an order of magnitude lower than the rest of the representatives of this kind of technology. It must be clarified that the lower part of the iron is not made entirely of ceramic. Usually they make ceramic spraying of small thickness on a metal plate. The ceramic surface has certain advantages:

- the plate is able to heat up in a matter of moments. After heating, this material slowly gives off heat. Because of this beneficial quality, ceramic-soled irons are considered very economical in terms of electrical consumption;

- the slip coefficient of soles with ceramic spraying is much greater than that of others. This facilitates the process of ironing even difficult surfaces, such as dry laundry, and forces you to apply a minimum of effort.

Ceramics, with all its positive qualities, has a significant drawback - it is very fragile. When the iron falls on a hard surface, the lower part of the iron completely fails.

- Teflon. Provides the maximum safety of the smoothed surface. This material does not stick to clothing and does not burn it.

Disadvantages:

- short term of operation. With frequent use of iron, Teflon is erased from the plate. That is why users prefer to use irons with plates of other materials;

- extremely susceptible to minor damage. Even an ordinary button can leave a scratch on the Teflon surface during ironing.

- Stainless steel. Very durable and practical material, extremely popular among users.

Pros of stainless steel:

- material is inexpensive, very popular. Irons with stainless steel soles have an affordable pricing policy;

- high-quality stainless steel is very durable, and can last for decades. But most often the electronic component of the device fails;

- stainless steel is immune to damage (scratches, abrasions, chips). Ironing clothes with buttons, fasteners, zippers will not do such a sole harm;

- not subject to corrosion. This is a very important aspect, since the iron is a device that is constantly in contact with water and steam.

Now plates made entirely of stainless steel can be found very rarely. Many companies, for example, Rowenta, prefer to use additional spraying over stainless steel. Rowenta covers the stainless steel with a layer of nanoglass. This increases ironing performance and provides the necessary glide.

- Aluminum. The material is inexpensive and practical, heats well and holds temperature.Soles made entirely of aluminum are now rarely used. Many companies create certain alloys with this metal, after which they file a patent for it. For example, a Braun eloxal iron sole has its own manufacturing features. Aluminum is oxidized by reaction with an electrolyte solution.

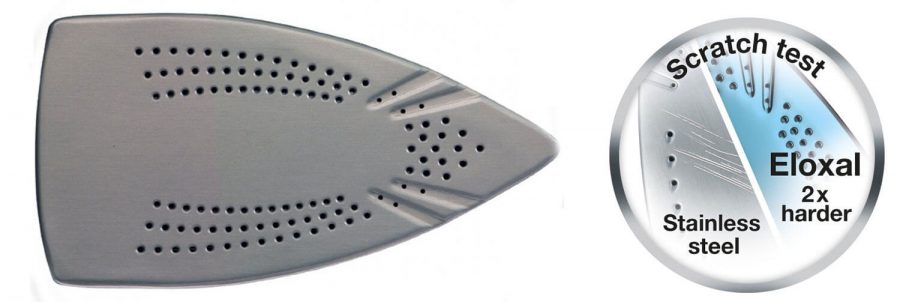

In addition to its advantages, this metal also has disadvantages. Its structure is very soft and, when interacting with solid objects, scratches and even chips may remain on the surface of the sole.

Sole eloxal: what is it

Braun is creative in creating new iron models. So a separate line of irons was born, which was called Texstyle. The main difference of this generation of devices is the sole, which is made using the latest eloxal technology. The base of the sole remains the same high-quality aluminum, which was also used in earlier models. But now, in the manufacture of the sole, the material is oxidized by interaction with an electrolyte solution. Such a procedure eliminates the main disadvantages of aluminum - softness and fragility. After oxidation, the metal becomes strong and becomes able to resist corrosion. From such an operation, the cost of the devices did not change much, but the quality of ironing increased, and the service life increased.

The main positive qualities of the eloxal plate:

- The lightness of the material. The weight of aluminum remained the same; its strength increased. With eloxal soles, you can iron things with hard objects. From contact with them, the sole material does not deform, and scratches, chips and scuffs do not appear on it.

- Corrosion-resistant properties. After electrolyte treatment, aluminum is resistant to corrosion. Rust and other traces of close contact with water will not appear on its surface.

- Improved glide. On the eloxal sole, the quality of gliding on the surface of things improves. The user makes even less effort when ironing things.

Eloxal technology is considered a new generation of alloys. Its qualities are proved by a large number of positive user reviews.

Saphir - a worthy answer eloxal

Braun does not stop there, and the sole for the iron, created using Saphir technology, is born. Braun uses stainless steel as its base material, onto which a thin layer of an artificial mineral called corundum is applied. This mineral in hardness is not much inferior to diamond, hence the name of the technology - Saphir. Spraying corundum provides the sole with extra strength of high quality.

Short afterword

The variety of irons is now quite large. But when choosing a device, you need to pay attention to the quality and durability of the device. The sole is the main element that most often fails. Therefore, the choice of material from which it is made is very important.

Sole of an eloxal or saphir iron? Which is better, the description which is presented above prompts. Saphir technology ensures long life. Eloxal provides the user with other positive qualities: improved gliding and ease of ironing. The eloxal sole allows you to turn your daily routine into a simple and time-saving action.