For several years there has been a debate about proper brewing among very experienced distillers with extensive experience: some argue that a classic distiller with the addition of a steam tank is quite enough to produce high-quality strong drinks, while others advocate column-type products. So what is better in practice - a moonshine still with a steamer or the same product, but equipped with a distillation column?

There are quite a few differences in design and purpose, and in this article we will try to give all the pros and cons of these devices, talk about their features and the principle of operation so that potential users can decide which device they need to purchase to improve their distiller, which model is worth buying and why.

Content

What is a steamer

The main purpose of this product is to protect the distillate from the spray of mash when it is boiling actively, because small droplets are captured by alcohol-containing vapors and transferred through the pipeline to the cooler, thereby polluting the final product.

This behavior is typical for all types and recipes of mash. In addition to protection, the steam filter filters fusel oils, since the temperature in it is slightly lower than in the upper part of the distillation cube and the steam pipe. All fractions with a higher boiling point than alcohol are condensed in it, and alcohol-containing vapors are sent further to the refrigerator - this is the only similarity with column-type products.

Loss of strength in this device does not occur, and if you purchased a collapsible version, you can flavor the final product at your discretion, for example, citrus peel, aromatic herbs or dried fruits and berries. The difference from alcohol infused with the same ingredients is enormous: there is no color, nor bitterness, which gives the peel of a lemon or an orange.

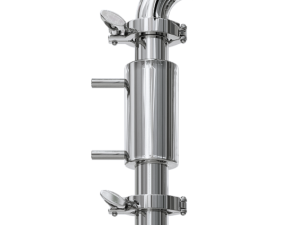

Distillation column

This complex design has special nozzles or plates inside, the dummy column will only perform distillation functions after filling nozzles to trap different fractions, so do not confuse these two designs, which are different in functional features.

The nozzles have a complex filling and multiply increase the inner surface of the column, where the main deposition of various fractions. At different parts of the product, the boiling point of alcohol is maintained, so the vapors pass unhindered, and fusel oils and other harmful impurities fall into the condensate. Copper perfectly captures sulfur compounds, forming insoluble compounds, so distillation columns are made from it to distill mash from grapes or grain.

The product in the upper part has a reflux condenser - it helps to observe a very strict temperature regime during the selection of fractions, due to which the effective purification of alcohol-containing vapors occurs. The column can make aromatization if the manufacturer has provided for the installation of additional blocks in the main structure - a special basket is separately purchased for embedding flavorings in it.

Their differences

The sukhoparnik is in contact with the environment, and temperature errors are eliminated in the column due to the presence of a reflux condenser; distillate is cleaned of harmful impurities to the maximum. Moonshine stills with a distillation column allow you to get absolutely pure alcohol with a maximum strength of up to 96 degrees, and similar models with a steamer mainly drive moonshine with a strength of 80-85 degrees.

Only experienced wine distillers due to jewelry adherence to technology reach the highest limit of 90. The columns clearly select the so-called heads, and with the presence of a steamer all fractions are more blurred, but you can get the final product with the smell and taste of the feedstock. On the column it is also possible, but only with less stringent observance of the temperature regime.

In terms of cost, they also differ significantly, but we will talk about this in detail in the following sections. The verdict so far is this: a distillation column is more expensive than a classic moonshine brewing apparatus, but it can significantly expand the possibilities of home production of strong drinks.

Where distillation column and steam vessel are used

At first, a little history: rectification became known at the beginning of the XIX century, it is one of the most important technological processes in the alcohol and oil industries. Today it is used in various fields of chemical technology, where the isolation of fractions in pure form is of particular importance.

Distillation columns are used not only in distillation processes - the same principle of heat exchange between vapors and liquid is used both in simple laboratory devices and in rather complex industrial plants of oil refining, chemical, gas, brewing and many other industries. The diameter of industrial devices can reach 16, and a height of 90 meters or more.

Unlike column type devices, a steamer is used only in the process of home brewing as an additional element between the tank with the brew and the coil. In it, the separation of harmful components takes place, and the alcohol-containing steam is sent further for cooling and collection into a container. It is used for more effective filtration and additional aromatization of moonshine.

As a result of passing through a sukhoparnik, the drink turns out to be stronger, better refined, saturated aroma and taste of the original product, for example, strong chacha has a persistent smell and taste of grapes. Each distillery makes a decision on the appropriateness of its use, but experts believe that this device will be useful to obtain a strong and well-cleaned final product.

Which is better to choose

As a result of the comparison, we found that the steamer and distillation column are completely different products that are used in moonshine for specific purposes:

- Sukhoparnik is an additional module, and not an independent device, like a distillation column.

- Such a device is used to ennoble the resulting moonshine, and the column serves as a source of high purification of the resulting alcohol of great strength.

- Cost: the price of a steamer is in the range of 300-500 rubles, the most complex designs are sold no more than 1.5 thousand rubles. Column-type rectifiers are much more expensive: the simplest product with a low column will cost the consumer at least 7 thousand rubles.

The conclusions from the foregoing are as follows: buying a sukhoparnar is justified if you already have a reliable moonshine and want to get not only pure and strong alcohol, but also elite varieties such as brandy or whiskey, as well as homemade liquors, for example, from blackcurrant or chokeberry.

A distillation column is purchased by those distilleries that need large volumes of pure alcohol, otherwise such an acquisition would be unprofitable.

Rating of the best models

moonshine stills with a steamer

20/35 / t double distillation moonshine with drawers

- Material: AISI 304 steel

- Productivity: up to 0.6 l / h

- Distillation cube volume: 20 l

- Wall thickness: 1.0mm

- Throat Diameter: 35-40 mm

- Assembly height: 62 cm

- Weight: 4.2 kg

- Product strength: up to 84%

- strength of all parts

- normal construction

- quality end product

- construction of the drawer is not thought out

Probably, the quality of production is lame at the plant, because the expansion of the cooler pipes is bad, the drawers are designed so that, for example, it is impossible to remove the Panchenkov nozzle for washing and not damage it unrealistically. It is necessary to work only with the analogue of stainless steel, and its effectiveness is much worse than copper or combined, but it can be washed assembly.

MAGARYCH Magarych Mashkovsky Export 20

- All parts are made of food grade stainless steel.

- Productivity: up to 2.0 l / h

- Distillation tank volume: 20 l

- Wall thickness: 1.0 mm

- Neck Diameter: 100 mm

- Dimensions: 240x240x770 mm

- Empty weight: 5.9 kg

- build quality

- original leather inserts with logo

- excellent compactness

- very low productivity

Phoenix People's 20 liters

- Material: AISI 430 steel

- Productivity: up to 3.0 l / h

- Distillation cube volume: 20 l

- Wall thickness: 1.50 mm

- Neck Diameter: 120 mm

- Dimensions: 280x280x520 mm

- Weight: 4.5 kg

- Product Strength: 60%

- modern design

- quality steel

- weak side seams - drip in a year

- in a dry steam insert of iron, rusted in two weeks

- small coil - poor cooling

MAGARYCH Magarych Mashkovsky Export 12

- All parts are made of food grade stainless steel.

- Productivity: 2.0 L / h

- Distillation tank volume: 12 l

- Wall thickness: 1.0 mm

- Neck Diameter: 80 mm

- Dimensions: 270x270x600 mm

- Empty weight: 3.5 kg

- great design

- quality of all parts

- can be added to the king to improve quality

- narrow neck

- low productivity

Phoenix Miner 12 liters

- Material: AISI 304 steel

- Productivity: up to 3.0 l / h

- Distillation cube volume: 12 l

- Wall thickness: 1.5mm

- Neck Diameter: 120 mm

- Dimensions: 230x230x620 mm

- Weight: 4.6 kg

- compact enough

- thermometer integrated in the tank

- collapsible glass steamer

- high performance

- not found

distillation columns with a steam tank

Good Heat Universal System Source 25 liters

- All parts are made of food grade stainless steel.

- Productivity: up to 4.0 l / h

- Distillation tank volume: 25 L

- Wall thickness: 1.5-2.0 mm

- Neck Diameter: 115-120 mm

- Dimensions: distillation tank - 300x300x355 mm, columns - 38x38x690 mm, reflux condenser - 60x150 mm, complete structures - 300x300x1260 mm

- Maximum strength: 90%

- high reliability

- build quality

- heating on any heat source

- three degrees of purification

- full set

- not found

Cuprum & Steel Star Plus 40 liters

- Material: stainless steel body, column - copper

- Productivity: up to 4.5 l / h

- Distillation volume: 40 L

- Wall thickness: 1.5mm

- Neck Diameter: 120 mm

- Dimensions: 350x350x1000 mm

- Product Strength: 70-80%

- Warranty: 5 years

- copper + steel AISI 430

- latest construction steam tank

- works on induction cookers

- PVC water hoses

- for collecting distillate - a hose made of medical silicone

- not found

THERMOSPHERE Ararat-7 20 liters

- All parts are made of food grade stainless steel.

- Productivity: up to 7.0 l / h

- Distillation tank volume: 20 l

- Wall thickness: 1.5 mm

- Product bottom: three-layer, thickness 5 mm

- Neck Diameter: 320 mm

- Dimensions: 320x320x670 mm

- Empty weight: 7 kg

- triple distillation at a time

- three degrees of purification

- bubbling sukhoparnik - removes 98% of impurities

- not found

Domestic Thermosfera plant, Balashikha, Moscow region - the only company working on German technology and equipment from Germany. Ararat-7 was developed in conjunction with German experts, in 2016 was recognized as the best product of the year. Popularity awarded People's Brand Award.

Good Heat Universal flagship system 50 liters

- Material: AISI 304 steel

- Productivity: up to 4.0 l / h

- Distillation volume: 50 L

- Wall thickness: 1.5mm

- Diameter: columns - 38 mm, neck - 120 mm

- Dimensions: 360x360x1220 mm

- Product strength: up to 80%

- tube fridge

- high degree of purification

- argon welding ensures tightness

- Digital Thermometer

- hoses for water and distillate

- not found

Cuprum & Steel Star Plus 30 liters

- Stainless steel body, column - copper

- Productivity: up to 4.5 l / h

- Distillation tank volume: 30 l

- Wall thickness: 1.5 mm

- Neck Diameter: 115-120 mm

- Dimensions: columns - 40x40x500 mm, refrigerator - 40x40x400 mm, complete assembly - 300x300x1000 mm

- Empty weight: 7.5 kg

- Fortress: 70-80%

- copper column

- steam tank with drain cock

- powerful flow-type refrigerator

- low water consumption

- suitable for all types of plates

- not found

findings

Products with distillation columns are much more expensive, but you get pure alcohol with high purity and excellent strength. When going out to 4 liters after simple manipulations to dilute to 40 degrees, we get 16 bottles of home-made vodka of 0.5 l each. This volume is quite enough for your needs, and you can also treat friends with relatives.