Some motorists desire to have a good sound in the car turns into a pursuit of records. There are even communities whose members aim to build systems with great power. Here it is considered the level of beginner acoustics in kilowatts. Not uncommon - a system with a capacity of 5 or more thousand watts. Not a single vehicle system is designed for such consumption. Therefore, we need a capacitor for the subwoofer, which at the moments of peak power take-off can compensate for the voltage drop in the network.

Content

Why do I need a capacitor for a subwoofer

To understand why the machine is equipped with a capacitive capacitor, it is worth recalling Ohm's law for a complete circuit. It is he who will help to understand what happens when the subwoofer abruptly reaches its maximum volume.

- Each battery has a parameter of electromotive force, which depends on the capacity of the device, its internal resistance and other characteristics.

- Until the moment when the amplifier and the entire sound installation as a whole do not exceed the battery capacity for consumption, the wiring works in normal mode.

- In periods when the subwoofer increases its volume and power consumption sharply, the battery is not physically able to satisfy its needs. Its electromotive force is not enough to maintain a stable voltage.

As a result of intensive power take-off for sound, the following occurs: operating currents grow, the battery cannot provide for needs, and the voltage of the on-board network drops sharply. As a result, subwoofer subsidence is observed (the speakers are choking), the amplifier operation becomes abnormal.

It is to stabilize the on-board network that requires electrolytic capacitors that give off power at the time of peak load. It should be understood that the average speaker in the car, like the entire audio system as a whole, does not always work even at rated power. During these periods of low consumption and currents, the machine with its generator charges not only the battery, but also the installed drive.

During periods of increased consumption, the capacitor discharges. This allows you to get a truly better sound without power drops and failure to set the front of the sound volume.

What to look for when buying?

The main thing that should be considered by a car owner who wants to buy an electrolytic capacitor for a subwoofer is the ratio of its capacity and system power. The rule is quite simple. The minimum limit is 650 to 850 microfarads per kilowatt. To simplify the calculations, it is recommended to take 1F per 1 kW of sound system power.

Ideally, if a capacitor with a capacity exceeding the nominal values is installed in the car. Other features of a good item are as follows:

- The scope of supply should include everything you need to install an electrolytic capacitor in the machine. These are the wires that connect the amplifier, and special protected brackets that exclude damage to the shell of the element and the emergence of other emergency situations;

- the pulse voltage of the capacitor should be 24 V. This is a sufficient margin (the corresponding on-board network operation parameter is from 12 to 18 V) so that the drive does not overheat during charging;

- For a sharp return of high power, the formation of high currents, the capacitor must have powerful connectors with thick leads and a large area. Responsible companies offer products with gold-plated contacts;

- A huge help, including for the convenience of monitoring the status of the drive during operation, are the charge indicators. This may be the simplest circuit with a series of LEDs or a digital display;

- if you need a drive that can be simply connected and counted on long-term stable operation - it is recommended to buy products equipped with a charge and condition monitoring system. Such models are necessarily equipped with an indicator.

Last, but not least, remark: saving on the purchase of an electrolytic capacitor for a subwoofer is not worth it. In specialized forums you can find many examples, videos and photos of the disassembly of cheap products. They clearly and accurately show the discrepancy between the real characteristics of the declared, and also describe the danger of using this type of drive.

Before buying an electrolytic capacitor, you should definitely look for reviews on specialized resources. Or - look through the ratings and get acquainted with the characteristics of suitable products on the website of their manufacturers. Today on the mass market both electrolytic capacitors and ionistors that are quite sensitive to temperature fluctuations are offered.

The installation of a capacitor in the on-board network, in addition to purely utilitarian results in the form of stable operation of the speaker system, has several more advantages. In particular, current surges are smoothed out during operation of the ignition system. Also, the operating mode of the onboard generator improves, as it begins to experience less consumption surge. And most importantly: the installed capacitor perfectly helps the starter in winter, giving power to the common network.

How to install a capacitor?

The most difficult thing is to install a simple capacitor that is not equipped with a charge control system. An empty network-attached drive may in some cases burn a connected amplifier. The following happens:

- an empty capacitor with very low internal resistance closes the circuit;

- passing currents increase sharply to a maximum, depending on the technical characteristics of the drive;

- currents in the circuit fall as the charge of the drive increases.

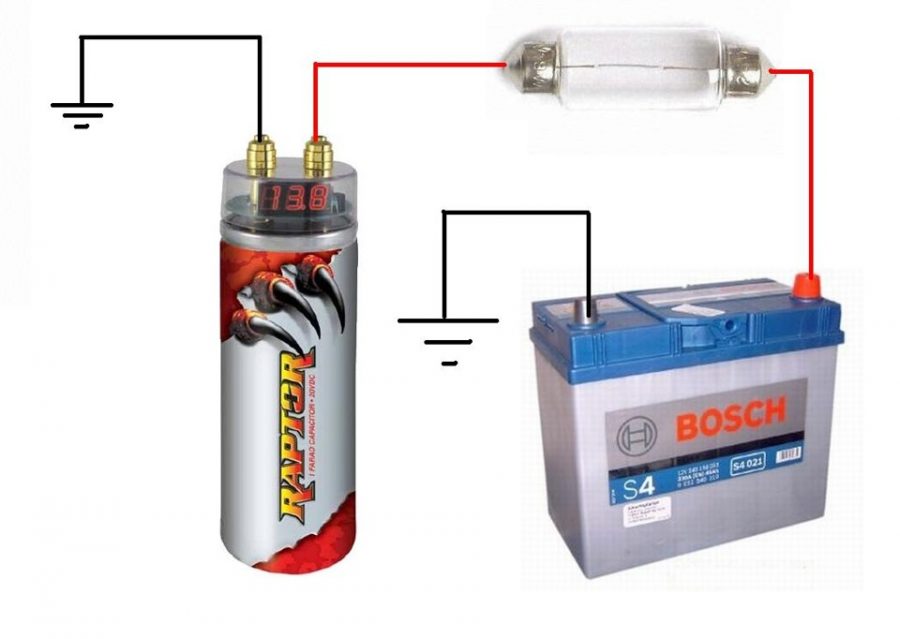

The initial current jump is so high that it is clearly not recommended to subject the amplifier and other acoustic components to such a test. Therefore, a capacitor without a charge control system is charged before being included in the on-board system. To do this, assemble a simple scheme.

The negative terminal of the capacitor is connected to the mass, the car body. The standard incandescent lamp for the machine is soldered to the positive, its second contact is connected to the positive terminal of the battery. The negative tap of the car battery is also commutated to ground, housing.

When you turn on the circuit, the following occurs: the lamp thread jerks up to maximum. As the charge accumulates, the luminosity decreases. When the lamp goes out completely, this means that the voltage on the capacitor is equal to the battery, there is no potential difference. The charge of the drive is full, it is carefully disconnected, preventing contact closure. You need to work in rubber gloves.

With drives that are equipped with a charge control system - you can not conjure. They are included in the general circuit without precautions. Built-in electronics blocks the primary current surge. This convenience drive is offset by some disadvantage. The capacitor can give a current limited by the parameter of the electronic charge control unit. This should be considered when buying a device.

Top 5 devices of 2019

Based on customer reviews, the 5 best capacitors for the subwoofer were selected, showing good results and a long service life. Among them are products of well-known brands, suitable for use by both beginners and experienced engineers in car audio systems.

Kicx flc 1.5

- good equipment

- ring terminal contacts

- reverse polarity protection

- charge level indication

- weight, dimensions

- capacity only 1.5 F

- low margin of operating voltage

The main advantage of this capacitor is the complete ease of installation. Convenient complete brackets and a reliable contact group are provided. The product shows excellent service life thanks to electronic protection and a special mesh.

MD.Lab PC-E1.0

- 1F capacitance with low measurement error

- compact aluminum case

- built-in voltmeter

- no reverse polarity protection

- low overvoltage margin

- meager equipment (condenser only)

This drive can provide only 18 V surge voltage. If this is enough - the device will appeal to experienced designers of audio systems. The capacitor can operate at temperatures from -40 to 60 degrees Celsius, has low leakage currents.

ACV CAP-5.0F

- overload protection

- incorrect start protection

- amplifier integration option

- the ability to connect multiple load units in series

- advanced electronic parameter control system

- indicator light and built-in voltmeter

- dimensions

- low impulse voltage

- own wiring diagram

- uncomfortable terminal blocks

The most comprehensive control of voltage and operation parameters, as well as the possibility of direct control from the amplifier side, are two bright features that distinguish this capacitor model. It will appeal to users who want to create a really powerful system. Capacities in 5F are enough for acoustics of 5 kW.

Kicx DPC 2.0F

- excellent power to size ratio

- built-in charge indicator

- built-in standby trip relay

- good surge voltage margin

- small area terminals

- meager equipment (condenser only)

- low working voltage 12V

This capacitor is very unpretentious. With some shortcomings, it allows overheating up to 95 degrees Celsius and will retain charge in the parking lot without using special connection schemes. The device will appeal to beginners, it is able to give out a pulse of 24V.

Neighing from the heart.

"The pulse voltage of the capacitor should be 24 V. This is a sufficient margin (the corresponding parameter of the on-board network is 12 to 18 V) so that the drive does not overheat during charging." Where did you get this nonsense? The power of a passenger car generator rarely exceeds 1 kW. No capacitor will increase this power at times. It has a different function. Learn materiel and do not powder people with brains.