Scroll compressors are a worthy alternative to other types of air blowers, especially reciprocating ones. In recent years, more and more companies have preferred a scroll type compressor to provide consumers with clean air without the slightest impurity of oil.

A scroll compressor is not cheap, especially equipped with a receiver. But for industries where, according to ISO8573-1 (2010) standards, the degree of air pollution should correspond to class “0”, it is the best choice.

In addition, given the low cost of service and high efficiency of the unit, its cost quickly fights off. Add to this absolutely clean air and silent operation - and it will become clear why air scroll compressors are so rapidly conquering the market.

Content

Device and principle of operation

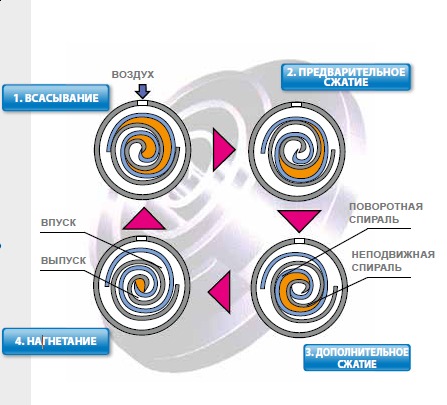

The principle of operation of a spiral type supercharger is based on the rotation of one spiral relative to another:

- the first - static - is fixedly fixed on the body;

- the second - dynamic - rotates around it, pushing a portion of compressed air to the output path.

The cycle is repeated continuously, eliminating sudden changes in air pressure, the so-called ripple. A single cycle consists of 3 stages.

- Initial, when air is sucked into the space released by the moving spiral. There are no gaps between the static and dynamic parts.

- Compression stage. As the spiral wraps, the incoming air is compressed, gradually moving toward the exit point.

- Final, when compressed air is ejected from the outlet and supplied to the consumer.

The number of revolutions of the drive shaft reaches several tens of thousands in 1 min. But unlike reciprocating compressors, there are no ripples that lead to early wear of components.

Expensive models of air blowers provide for the adjustment of the axial displacement of the spirals in order to adjust the maximum output pressure. For ventilation, a zero cycle is ensured without forcing.

The most common are electric compressors, but superchargers with diesel or gasoline power units are on sale. Helical gear compressor will last longer. It shows a zero level of slippage at maximum loads, differs in efficiency close to 100% and is easy to maintain.

The presence of a dynamic valve will prevent air from moving in the opposite direction if a high pressure is detected on the consumer. If the compressor is equipped with an air filter, then its performance will decrease slightly, but the resource of anti-friction seals, and therefore the unit itself, will increase. These elements are optional; they raise the total cost of the system. But the predictability of the compressor and its service life increase dramatically.

Areas of use

Scroll compressors are widely used in air conditioning systems, both domestic and industrial, as well as in a number of other areas:

- heat pumps;

- precise air concentration systems;

- in medical equipment;

- in food production (cold-storage plants, fruit storage, autoclaves for wine purification, food processing, etc.);

- in the chemical industry (for condensation of solvents, cooling of molding equipment, etc.).

In air conditioning systems, including split systems, spiral blowers are used because of the low noise level that allows you to install air conditioning in the bedrooms.Their working qualities do not change over the years, in contrast to reciprocating compressors, and due to the compact size (and weight), their influence on the external design of the split system circuit is minimal. Now consider in more detail other areas of application of scroll air compressors.

The medicine

A scroll compressor intended for use in medical facilities must be tested for compliance with quality standards:

- ISO 8573-1 (class 0) - the complete absence of oil impregnations in the supplied air;

- ISO7396 - requirements for piping systems for medical gases;

- HTM02-01 is the international standard for the quality of medical gases.

Only certified units are allowed for use in medicine:

- in dentistry;

- anesthesiology

- resuscitation and operating rooms;

- laboratories;

- departments of surgery, cardiology, intensive care, etc.

A scroll compressor for medical use prepares an air mixture with a very accurate gas concentration. Data is shown on the display, and the concentration of substances is controlled through the control panel (push-button or touch). Some models are equipped with an air dryer. Also, the device may have a warning system.

For a constant supply of the gas mixture, duplicate control systems are responsible. Even if one supercharger stops, operation will not stop. Modern electronics guarantee continuous operation, slightly reducing productivity.

The compressed air station, in addition to the compressor, includes:

- station control unit;

- Receivers

- air driers;

- air filtration system.

To protect the supercharger elements from corrosion, a polymer coating is applied to the parts of medical compressors.

Food production

The determining factor when choosing an air supercharger in food production is how its price (including depreciation) will affect the competitiveness of goods. Safety and productivity are also important, because possible legal risks from consumers of low-quality products can lead to closure of production in the worst case scenario.

They are used in various sectors of the food industry:

- packaging (production and movement of elements along the conveyor);

- baking stuffing;

- for pumps pumping liquids;

- high pressure nitrogen supply;

- pneumatic scissors (peeling, slicing nuts, onions, vegetables);

- preparation of food mixtures.

Compressed air is also used to drive mechanisms in production.

Polygraphy

Modern printing products are characterized by high quality images, as well as pages coated with a glossy layer. The demanding reader will choose the edition that is pleasant to hold in his hands and examine, therefore it is so important to use high-quality purified air for printing production.

The spiral supercharger provides the supply of purified air at constant pressure, avoiding extremes. The main places where the compressor is used in printing is:

- pneumatic drive of automated lines;

- air conditioning and dehumidification of indoor air;

- mixing solutions, paints;

- packing with compressed air;

- paper lamination.

The cleaner the air used to dry the printed pages, the less distortion there will be. Scroll compressors guarantee the stability of the drying equipment of the printing house.

Chemical industry

To create gas mixtures and move them at the enterprises of the chemical industry, compressors are used.The most common area of their use is the field of organic synthesis, where are produced:

- polymers;

- alcohols;

- ammonia;

- rubbers.

The standard use of compressed air is the transmission of a power impulse to working mechanisms (cranes, hoists) and conveyor lines. The highly specialized purpose of a scroll compressor is:

- the movement of fluids in the ejector;

- creation of a low pressure zone in the apparatus;

- Support for a given pressure in the air distribution network;

- moving gas mixtures through pipes;

- the creation of gas mixtures;

- injection or suction of fumes.

In industrial air purification systems, scroll compressors, which take up little space, benefit compared to reciprocating compressors due to their high performance and stable operation, without jerking and braking. To increase the productivity of chemical industry equipment, it is important to bleed air from the freon circuit in a timely manner, and also to reduce pressure before refueling.

Advantages and disadvantages

The undoubted advantages of scroll compressors include:

- smooth operation without vibrations and jerks;

- lack of "dead volume";

- Efficiency approaching 100%;

- silent work;

- compactness;

- no spring board needed;

- low cost of service;

- minimum wear of elements.

Of course, the complete absence of oil in the air is also an advantage of a spiral supercharger. But each coin has two sides, so do not forget about the shortcomings:

- fine tuning of the equipment is necessary by a professional;

- periodic replacement of spirals is required;

- a compressor without a dynamic valve will not provide the desired pressure level in the supply air.

For each production and equipment, you need to select a compressor with the appropriate technical characteristics. There is no perfect device that fits everything. Before buying an expensive unit, you must definitely consult with an experienced specialist.