Some consumers are still distilling mash with old-fashioned methods, using long-obsolete models of moonshine based on milk cans, aluminum pans with self-bent coils of dubious quality. Therefore, moonshine is obtained with a smell and not always of high strength.

Today, manufacturers produce various equipment for distillation at home not only of classic moonshine, but also of elite types of strong drinks such as brandy and whiskey. To find out all the nuances of modern equipment, the principle of cleaning, advantages and disadvantages, you need to read our article.

Content

What is a moonshine

The use of alcoholic beverages began more than three thousand years ago, even in the time before the new era, and the art of preparing strong drinks was always appreciated by any people - in ancient Greece and Egypt only priests knew this secret.

The design of the primitive apparatus for moonshining consists of three main elements:

- Capacity where the mash is heated.

- Pipeline with a coil.

- A tank with running water, our ancestors used to cool a stream or a river.

Under the tube from the coil, any container was substituted, where moonshine also flowed.

The performance of such an archaic device was small, the cleaning was symbolic, the smell was in the whole district, and the final product was bluish, but was in great demand. The popularity of home-made alcohol still occupies a leading place among liquors and tinctures.

Second type

Today in the world of home-made lovers of various drinks, factory-assembled products are appearing that are ideal for beginner moonshiners, because they do not require much effort. These devices for home use are equipped with perfectly sealed distillation cubes, the material for which is copper or stainless steel (high-grade steel).

The quality of all parts is quite high, and the connections are sealed with silicone gaskets, the cube has a built-in thermometer for temperature control, there are fittings for the drainage and supply of running water in systems with forced circulation. All models are equipped with PVC hoses, and a special-strength hose made of medical silicone is used to divert the finished product.

Main characteristics

In the first place is the distillation cube - the vapor formation process depends on the high quality of its manufacture, in addition, it must be equipped with a thermometer.

Body material

Most modern moonshines for use at home are made of AISI 304 or 430 stainless steel. The next most popular metal is copper, but this product is not suitable for a beginner, because you need to train on a simpler model so as not to ruin the device, whose price is quite high.

Aluminum products gradually disappear from the market, because when heated, this metal is able to react with the degenerate and add substances to it that cannot be removed during subsequent distillation.This metal does not pass the suitability test; doctors do not recommend using it.

Cooling circuit

Beginner winemakers are interested in the important question of how to organize cooling, for example, in classical devices a coil is used, and columns use a reflux condenser. Tubular refrigerators are used in the brew column - they divide the vapor stream into several tubes at once, where active cooling occurs due to running water and alcohol condensation.

Filtering mechanism

For example, a universal classic distiller is necessarily equipped with a dry steam tank, because it is there that the separation into fractions takes place - heavy ones are deposited at the bottom of the device, and lighter ones are sent further. In a classical column, this stage occurs in a slightly different way, so at the output we get a odorless liquid and harmful impurities.

This design provides an ideal end product with high strength up to 90% and higher, and cleaning reaches 98%. As a rule, double distillation is not performed, in comparison with some other models.

Equipment

This parameter is taken into account when choosing a model, experts assure that all factory products must be fully equipped - when unpacking, the user only needs to fill in the prepared mug, assemble the device, connect all the necessary hoses and put the product into operation. But in practice, not all manufacturers invest in hoses, especially on budget models.

Principle of operation

Any home brewing apparatus is designed to distill mash into raw alcohol, and the process itself is divided into several stages, regardless of product design:

- Heating the mash and bringing it to a boiling point. Its composition is quite diverse - aldehydes, acetone, wood alcohol and other components harmful to humans, each ingredient has its own boiling point. The total amount of impurities is 8-10% of the total volume, and 90% is alcohol and fusel oils. The initial boil begins already at 78 degrees.

- Ethanol boiling point under ideal conditions 78.4C, fusel oils boil at 80-85 degrees, so heating continues so that all fusel oils evaporate.

- Vapors from the tank are sent to the sucker, all harmful fractions settle in the form of condensate, because the temperature here is below their boiling point.

- Alcohol-containing vapors are sent to a cooler, where they also condense and by gravity accumulate in a container placed under the tube.

The functional features of each model are individual, but the principle of operation is identical. To find out all the nuances on which the work of all modern moonshines is based, you need to know their types and design, but we will talk about this in detail in the next section.

Types of moonshine stills

To understand the varieties of modern products for brewing, you need to find out their differences from each other in the design and analyze the process technology, as well as ease of use.

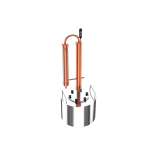

Distiller

A high-quality device has a more complex device - it is covered with an airtight cover or made of a molded structure with a neck, which is closed with a flange, and fixing is done with lamb. The housing is equipped with an overflow valve and a thermometer.

The main components of its construction:

- container for mash;

- cap or flange for the neck;

- thermometer;

- check valve;

- steam exhaust pipe;

- coil;

- water cooling.

For such products, performance is at a fairly high level, which for many users is the main condition.

Apparatus with a steamer

A special device where fraction separation takes place is located between the main tank and the cooler with a coil or a tube cooler.Today, all manufacturers install similar new generation devices on their models, because this allows you to get moonshine of the same quality as with double distillation.

The essence of the work of a steamer: it separates alcohol-containing vapors from fusel oils and other impurities, which have a higher boiling point, and therefore condense in its body. This device is also used to flavor alcohol by adding spices inside the discretion of the user.

Cleaning, according to leading experts in this field, is carried out more efficiently, and as a result we get a better drink at the output. Such products are suitable for the distillation of elite varieties of domestic alcohol.

Electric heating

Such devices differ from the basic one or products with a steam tank only by the presence of a heating element in the main tank. Electric heaters, one or two, are installed at the very bottom of the distillation cube, they are quite reliable and safe during operation. Judging by the reviews of experienced moonshiners, it is better to buy a device with two heating elements and a temperature controller: in this case it will be much more convenient to control the boiling temperature of the mash.

Oriental motives

A unique apparatus in design, reminiscent of the Aladdin fairytale lamp, the alambik is completely made of copper, because it has high thermal conductivity. The cost of such a product is quite high, but such devices are bought for an original gift to lovers and connoisseurs of home-made strong drinks.

Here, quality and reliability are of paramount importance: the classic version of the alambika has a lid that resembles an onion in shape, and all the components of the structure are made by minting on copper. Initially, this device was created in the East for the manufacture of medicines, but once in Europe, it was used for the manufacture of perfumes.

In the 15th century, they tried to overtake sour wine in it and got alcohol at the outlet. The main condition: insist on the mash for this device in an oak barrel, then at the exit you get brandy or whiskey. With it, they make good quality homemade wine. On sale there are quite voluminous options that allow you to overtake 13-25 liters of mash at one time.

They have no drawbacks, except for a high price, they are highly reliable, but they are not used for moonshine - they are designed to produce noble drinks, for example, high-end whiskey or brandy, some craftsmen make strong drinks of excellent quality, but a lot of experience is already needed here.

Mash column

Its other name is a film column, which was considered good if the following requirements were met:

- A diameter of at least 25-28 mm, a height of 30-50 times greater than the internal diameter.

- The reflux condenser must be powerful and controllable in order to extinguish the high heating of components not higher than 78 degrees.

- Fine adjustment of water cooling to the reflux condenser using a needle-type valve.

- The water supply to the reflux condenser and the refrigerator should be separate.

- The presence of a thermometer in the upper part of the column.

- The performance of the refrigerator should fully ensure high-quality cooling during the first and second stages.

A modern brewing column has a diameter of 40-50 mm, a height of 75-100 cm, a distillation cube with a capacity of 20-30 l, liquid selection of fractions and automatic control, the resulting alcohol can be drunk immediately, without exposure to it in an oak barrel, as was done previously.

Distillation column

This design is intended for the manufacture of purified alcohol 96%, which is subsequently used as the basis for various home-made alcoholic beverages. Key Details:

- Capacity for heating alcohol-containing mash.

- Pipe or drawer, which is the body of the column.

- Nozzles for filling the pipe.

- Dephlegmator.

- Distillate selection unit.

- Refrigerator with a coil or tube type with a permanent connection to the water supply.

- Connection and control details.

Household distillation columns are the products of a new generation, in comparison with other models, they occupy the highest level, becauseproduce perfectly pure alcohol of high strength.

the column can be called a new generation of moonshine, because it produces the best quality alcohol.

Some Chinese firms offer Russian consumers their original products for home brewing, but they do not withstand competition in terms of reliability and build quality, although some models deserve attention.

Advantages and disadvantages

Each device has its drawbacks and advantages, which are better discussed when describing specific models, in general, we can say that, despite their diversity and simple use, some consider them a relic of the past, probably these people are simply not in the subject, as is customary today talk. Today's devices are more popular today than ever - they occupy high places in the rating of household appliances, but are not considered essential goods.

How to choose a moonshine

First you need to find out the most important parameters, and then proceed to the selection of a fairly extensive range of modern moonshines.

Volume

For the home, the best option would be a product with a tank of up to 20 liters, because you are not going to sell products on the side, which, by the way, is punishable by law. When buying in a store, find out from the sellers how much devices are available for sale, and then see its technical nuances.

Material

When buying a device in a store, be sure to find out what metal was used in its manufacture: the best models are made of special grade stainless steel. The wall thickness is also important, especially pay attention to the bottom: it is better when it is layered and thick.

If the walls and bottom of the apparatus are thin, then the mash can burn, and you will hardly like the taste and smell of the product at the outlet. The ideal option when the walls are 2 mm thick is a guarantee that the product will not fail during active heating, and the mash will not burn.

Performance

Many manufacturers indicate this parameter in terms of diluted alcohol, for example, 4 liters per hour can mean in practice only 2 liters of alcohol, and diluting it to the state of vodka, we get twice as much.

Cleaning

The quality of purification from impurities is of primary importance, with an excellent indicator, re-distillation disappears, and this is a decent saving of effort and money, not to mention the use of energy and water.

Equipment

You should not be shy and check the complete set before paying for the goods: all products from the factory must be fully equipped, have a guarantee of at least 12 months. The kit includes hoses for water supply and alcohol selection, spare gaskets made of silicone, not rubber, which, when heated, will spoil the whole process with its smell, a thermometer and an alcohol meter.

The best models

Wagner 20 liters

- Case material: AISI 430 steel, mirror type

- Productivity: during distillation - 1.0-1.5 l / h, total - 7.0 l / h

- Distillation cube volume: 20 l

- Wall thickness: 2mm

- Neck Diameter: 105 mm

- Dimensions: 250x250x500 mm

- Weight: 5.1 kg

- Warranty: 12 months

- idle design

- high reliability

- great, modern design

- high quality of the resulting product

- not found

The Wagner household distiller is a budget model of the popular Finland trademark with a non-separable dry steam boiler having a drain cock for filtered fractions and a digital thermometer.

Wayne Germany Luxury 20 liters

- All parts are made of food grade stainless steel.

- Productivity: up to 2.0 l / h

- Distillation tank volume: 20 l

- Wall thickness: 2.0 mm

- Column: height - 600 mm, diameter - 400 mm

- Dimensions: 270x270x650 mm

- Empty weight: 4.5 kg

- Product strength: up to 95%

- up to four Panchenkov nozzles

- three-thread heat exchanger

- two thermometers on the body and the column

- drain cock at the bottom of the distillation cube

- not found

Dobrovar Katyusha Suite with a steam tank 10

- Material: AISI 304/430 steel

- Productivity: 3.0 L / h

- Distillation cube volume: 10 l

- Thickness: walls - 1.52.0 mm, bottom - 2.0-2.5 mm

- Dimensions of the tank: 210x210x370 mm

- Weight: 7.6 kg

- Warranty: 5 years

- effective cleaning of all types of impurities

- time saving

- universal distillate qualities

- heating only on gas or induction type stoves

- large dimensions

Finlandia Plus 12

- Parts made of food grade stainless steel

- Productivity: up to 2.5 l / h, with repeated distillation - up to 5 l / h

- Distillation tank volume: 12 l

- Wall thickness: 1.5 mm

- Diameter: mouths - 115-120 mm, containers for mash - 220 mm, connecting tubes - 16 mm, fittings for water - 6 mm

- Volume of a steam tank: 480 ml

- Empty weight: 4.5 kg

- high quality of all parts

- two bimetallic thermometers

- two collapsible dry steamers

- not found

THERMOSPHERE Geyser Classic 30 liters

- Case material: AISI 304/430 steel

- Productivity: 2.0 L / h

- Distillation volume: 30 L

- Wall thickness: 2.0mm

- The diameter of the tubes of the refrigerator: 12 mm

- high build quality

- argon welding

- perfect polish

- stamped flange

- full set

- not found

Phoenix Miner 15 liters

- Material: AISI 430 steel

- Productivity: up to 3.0 l / h

- Distillation volume: 15 L

- Wall thickness: 1.50 mm

- Neck Diameter: 120 mm

- Dimensions: tank - 280x280x250 mm, products - 280x280x570 mm

- Weight: 5.8 kg

- Product Strength: 60%

- price-quality ratio

- factory equipment

- high performance

- not found

Phoenix Economy 30 liters

- Case material: AISI 304/430 steel

- Productivity: up to 3.0 l / h

- Distillation volume: 30 L

- Thickness: walls - 1.0-1.5 mm, neck flange - 1.5 mm

- Neck Diameter: 110 mm

- Dimensions: 300x300x660 mm

- Weight: 6.0 kg

- Warranty: One Year

- great build

- material quality

- precise fit of all parts

- not found

MAGARYCH Premium BKT 12

- All parts are made of food grade stainless steel.

- Productivity: 1.4 L / h

- Distillation tank volume: 12 l

- Wall thickness: 1.0 mm

- Neck Diameter: 80 mm

- Dimensions: 220x220x530 mm

- Empty weight: 3.6 kg

- modern look

- copper coil

- dry tank without drain

- thin metal

Pervach Economy 12T

- Case material: steel 08X18H10T

- Productivity: up to 2.0 l / h

- Distillation cube volume: 12 l

- Thickness: walls - 1.0-1.5 mm, neck flange - 1.5 mm

- Throat Diameter: 40 mm

- Dimensions: 230x230x380 mm

- Weight: 5.5 kg

- Warranty: One Year

- automatic process

- flow cooling

- excellent product quality

- not found

Hanhi Steel 14

- All parts are made of stainless steel 12X18H10T

- Productivity: 3.0 L / h

- Distillation tank volume: 14 l

- Wall thickness: 1.5 mm

- Capsule bottom: 6.0 mm

- Neck Diameter: 80 mm

- Dimensions: 250x250x530 mm

- Empty weight: 4.5 kg

- Service life: 12 years

- for any sources of heating

- low water consumption

- increased cleaning

- not found

findings

Technological progress is hurrying forward, over the past few years, the production of home-brewing products has filled the market with the latest models, among which it is very difficult to make a choice - there are so many materials and technical parameters that are similar in quality. There is only one way out for the user: to trust the domestic manufacturer, because the models have been tested for years of operation, and the reliability is quite high.

The review is not entirely correct. You compare devices of different generations as well as different types. I used such reviews when I bought a moonshine. As a result, I bought a rare shit that went back literally immediately after delivery. I replaced the schnapser classic distiller on the advice

I have a Schnapps Extra 2018 device.This is my 3rd moonshine and moonshine is very high quality. The device is good and I use it without any problems. I believe that he deserves to be in the top of this rating. It has many upgrades and improvements, which improves the quality of moonshine.

Schnapper Extra is a device of a slightly different level. The devices presented in the review are already outdated and it is not entirely correct to compare the extras with them.