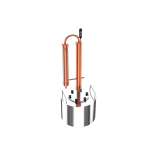

To prepare strong and clean homemade alcohol, you must clearly know the technology of distillation and use the latest technological advances to clean moonshine from harmful impurities. It is the reflux condenser, which is used quite often in the construction of a moonshine, plays the role of a reliable filter that eliminates all harmful phlegms called heads and tails.

The design and dimensions of such devices are different, some experienced distilleries independently make such products, but for a better screening of all impurities it is better to buy a factory model. What does the reflux condenser look like, its purpose and principle of action, you will learn by carefully reading this article.

Content

What is a reflux condenser

This is a device that carries out the condensation of phlegm contained in alcohol-containing vapors leaving the distillation cube. This device has several names, there is a long debate about its necessity, some moonshiners claim that its use increases the distillation time.

This statement is rather controversial, but the fact that these products clean fumes from fusel oils and other harmful impurities is beyond doubt. For a simple moonshine still, steam generators are used, where fractions having a boiling point higher than alcohol are deposited, in addition, such devices prevent the penetration of small splashes of mash during its boiling.

The design of any sukhoparnik differs in a rather primitive structure, but it can be improved, and as a result, moonshine will only become cleaner, get rid of an unpleasant smell. The reflux condenser is a kind of sedimentation tank in which, with active purification, almost all fusel oils settle, which spoil the taste and smell of moonshine with their presence, they are the main cause of poisoning by a low-quality distillation product.

Main functions

Moonshine stills differ in design, but they work in the same way, but if they don’t have a steamer and a high-quality cooler, getting a high-quality strong homemade drink will be very problematic. Most likely, the output will be moonshine of low quality and taste with a characteristic smell of the raw materials from which it was prepared.

Each part of the distillation apparatus performs its functions, so the right reflux condenser helps:

- Improve the taste of homemade alcohol, eliminate unpleasant odor and taste, as well as influence the strength of moonshine.

- To avoid the penetration of the smallest particles of boiling mash into alcohol-containing vapors, which significantly affects the quality and taste. This protection does not require re-distillation.

- Separates the heads and tails; their absence greatly enhances the final product.

- Alcohol begins to boil at a lower temperature than fusel oils and other harmful impurities contained in the original product - Braga, but for the effectiveness of the whole process it is heated to an active boil.

- Evaporating alcohol enters the steamer, in which the boiling point of alcohol is maintained. Other impurities condense on the walls of the device and drain into its lower part.

- The cleaned vapors continue to move towards the cooler and turn into a good quality strong drink in it.

- Le Chatelier;

- Bunsen

- Christmas tree type;

- nozzle;

- Dimroth.

- Significantly increase the purification of the final product, ensuring the removal of all foreign impurities during the passage of alcohol-containing vapors through the structure. The obtained moonshine does not require repeated distillation; it is of high strength, differs in its original taste and pleasant smell.

- If the device is made in the factory from high-quality food steel, then the distillate does not need to be cleaned either by mechanical means, or even less by chemical substances.

- When the reflux condenser is mounted in a column, the distillery receives a top-quality drink with a strength of 96% at the outlet.

- The use of dry steamers in moonshine stills will effectively clean moonshine, no chemical methods of this level of purification can provide.

- The reflux condenser is inherently an insurmountable barrier for small sprays of a boiling base from which distillate is distilled, its use ensures that the second distillation disappears completely.

- Sukhoparniks are used for flavoring - here each distillery can use his imagination without restrictions.

Sukhoparnik can be used to flavor moonshine: if it is of a collapsible type, then various flavors are placed inside: lemon or orange peel, spices or dried berries, lovers add cinnamon sticks for tartness. Some moonshiners add several dry steamers in a row, which allows to achieve a high strength of the drink, an excellent option when the dry steamer is glass: this allows you to visually monitor the level of filling.

Column-type distillation products necessarily have a reflux condenser at the highest point of the structure, in addition, the column pipe itself, made with a tsar, also plays the role of a filter - this is the design that allows home distilleries to produce pure alcohol 96 degrees, a regular device of this quality cannot reach its limit - 80% density.

How does it work

The principle of operation is based on the following:

The reflux condenser, in its essence, is an effective barrier to the path of the sivuha and all harmful impurities, it is it that can significantly improve the taste, maximize the strength of homemade alcohol. In the design of modern devices for home brewing, two dry steamers are used at once: one for cleaning, and the other for flavoring.

For effective purification and aromatization of elite varieties of homemade strong alcohol during their distillation, for example, brandy, rum and whiskey, three reflux condensers are used, which allows you to get a very high-quality drink at the exit.

Kinds

All products used in the modern production of home-brew can be divided into two main classes: film type and the rest.

The only difference is that in the first embodiment there are no additional elements - phlegms come in contact with boundary pairs and condense on the vertical walls of the structure, and evaporate from it when heated.

Here are just a few types of reflux condensers with various fillers from inert materials:

The name may be different, it all depends on the details used and the principle of operation: for example, the Dimrot product is based on the standard action, when the condensate that has precipitated is returned to the waste container, and not to the vessel with the finished distillation product. It is this design that experts consider practical and convenient to use.

The whole structure is made of tempered glass, which is able to withstand high temperatures; the taste of moonshine never spoils from such a material. For cooling, it is enough to use running water from a normal water supply.

Main advantages

Moonshine stills with dry steamers and distillation columns with reflux condensers are a special type of home equipment with devices for the efficient purification of distillate vapor. The presence of such products allows you to:

The above methods make it possible to obtain strong alcoholic drinks at home that are much superior in quality to store counterparts, and the variety of diluted material can be a significant competitor to factory-made liquors and liquors.This is not only a matter of distillate - only high-quality, natural ingredients are used for the production of home-made liquors and distillery liquors: dried berries or fruits, and essences and chemical extracts are added to the factories.

findings

An experienced home distillate distillation master can boast not only high purification of moonshine, as pure as a baby’s tear, but also make liquors, liquors, and fragrant compositions based on the resulting product. Surprising relatives with flavourless homemade vodka is one thing, and to please them with original elite varieties of homemade alcohol such as chacha, whiskey, brandy, rum or thick plum brandy is already aerobatics.

For excellent distillation, it is necessary to purchase equipment made of high quality materials - food or medical stainless steel or copper, which will be the key to long operation and excellent performance.