The advent of printers for three-dimensional printing was at one time a real breakthrough in the world of technology. Many prophesied that these devices will quickly find their place both in industry and in everyday life. But in reality, 3D printing remains rather a privilege for the average user. What prevented them from spreading everywhere?

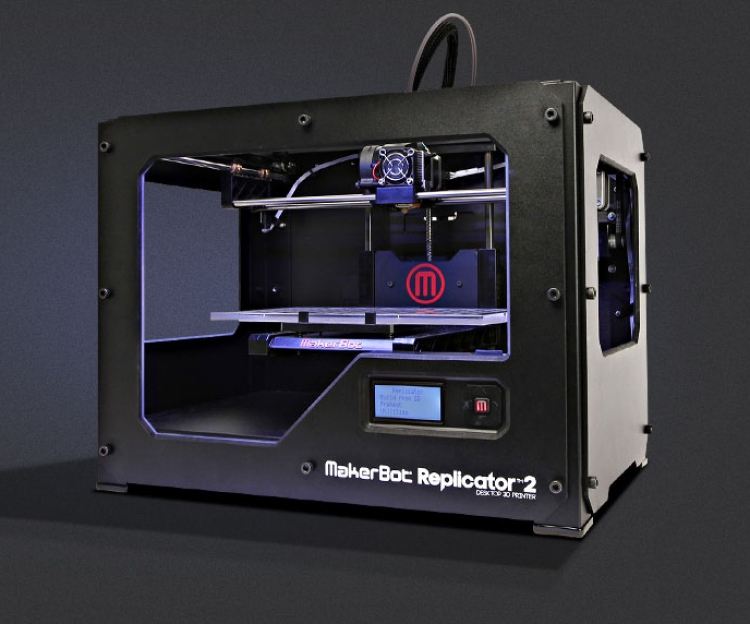

What are 3D printers

The essence of the device is the gradual reproduction of a three-dimensional computer model using specific material. Modern 3D printers can create an object from both plastic and polymer resin, rubber, gypsum, and even metal.

Scope of application

3D printers are widely used in production, where they have already become an indispensable part of the process. Most commonly, these devices are used in such areas as:

- automotive industry;

- manufacturing parts for aircraft;

- biotechnology production;

- manufacturing of medical prostheses and artificial valves;

- robotics.

To reproduce the idea in the material, you need three-dimensional visualization of the project in a special program. You do not have to own 3D modeling to work with such a printer. In the libraries of special editors for devices, you can find options for the part from almost any area of life.

Why bulk printing is not popular

A decade ago, 3D printer developers predicted that after just a couple of years, such a device would be available to any family. The idea to create a variety of household items was independently accepted by the general public with enthusiasm. Many already imagined how they would print toothbrushes and combs instead of buying them at the store.

But in reality, everything turned out to be not so simple - three-dimensional devices became widespread only in some industries and medicine, and for domestic consumers they remained a dream.

There are a number of reasons for this:

- high cost. Dreams of cheap products made at home on a printer still remain dreams. In fact, not only buying a device costs a round sum, but consumables require significant costs, which outside the factories and workshops is impractical;

- print quality. Industrial models of 3D printers cost hundreds of thousands of dollars, while household appliances cost ten times less. However, the print quality of cheaper models is poor. Many users who actively print parts and elements of mechanisms note that finished products have to be brought to the desired state manually. Often requires additional grinding and polishing;

- uneconomical use of print media. When using household 3D printers, material is overspended. A certain proportion of the plastic goes into the trash and cannot be reused. In addition, simpler installations typically print parts for a long time, which increases energy costs;

- poor quality printed products.

Undoubtedly, industrial plants differ in that the result of their work meets all the requirements for strength and quality. More affordable printers are mainly used for printing from plastic. Naturally, the plastic part will be inferior in characteristics to a more durable metal or made of their hydrocarbon fiber.

Despite the fact that 3D printers are not as widespread as the designers planned, these devices still have a future. Work on improving the technology of three-dimensional printing continues, so it is possible that such a printer will be in every house in 10 years.