The quality of the stitch depends on the choice of the type of shuttle in the sewing machine, because this mechanism interweaves the working threads. The strength and reliability of the seam and the presentation of the product depend on how skillfully the sewing loop is made. The industry uses various kinds of shuttles in sewing machines. How to choose the most suitable type, satisfying the request and not overpay for unnecessary functions?

The quality of the stitch depends on the choice of the type of shuttle in the sewing machine, because this mechanism interweaves the working threads. The strength and reliability of the seam and the presentation of the product depend on how skillfully the sewing loop is made. The industry uses various kinds of shuttles in sewing machines. How to choose the most suitable type, satisfying the request and not overpay for unnecessary functions?

Content

What is a “shuttle” and what types of shuttles are

The word "shuttle" came from the word shuttle - a small boat. In sewing machines, this is the name of the workpiece, which moves back and forth on its axis when sewing fabric. Fans of sewing craft consider this part the heart of the machine. The final result of sewing or repairing the product depends on its work.

In the modern production of sewing machines, 3 main types of mechanisms are used:

- Pendulum.

- Horizontal

- Vertical.

In industrial sewing, the rotary type is most convenient. For lovers, the pendulum option is optimal.

It is impossible to select a sewing machine separately and decide on your own which shuttle mechanism to install in it. It is also impossible to install a horizontal version on a model with a vertical arrangement and vice versa. When choosing a sewing unit, the type of shuttle in the sewing machine, which is better to prefer, depends on the required load on the machine.

Pendulum type

These are the simplest mechanisms that have found application in budget models of machines. They are made of metal, withstand the loads that are possible with unprofessional use. They got their name from the movement according to the principle of the pendulum. Working on a typewriter with this type of working mechanism, a beginning seamstress or a lover of sewing for a family will quite calmly carry out all the necessary operations. Such models have a limited list of executable options, but this is quite enough for use at the household level.

Pendulum shuttles are patriarchs in their midst. They were installed on typewriters in the twentieth century, they are in demand in modern models of branded machines designed for rare use. They are easy to maintain, but require constant lubrication. It is these models that are installed on sewing machines with an electromechanical type of control.

Positive traits:

- Easy to maintain.

- Reliability.

- Availability.

In the event of a breakdown of the sewing machine with the pendulum model, it will not be difficult to find a master for repair and adjustment.

The disadvantages of these mechanisms include:

- A limited number of operations that they can perform.

- The need for constant lubrication.

- High noise level during the work.

- Poor line quality.

- Low working speed.

- Limited length and width of stitches.

- Great vibration.

To determine which shuttle is better in a professional sewing machine, it is worth understanding the intricacies of horizontal and vertical devices.

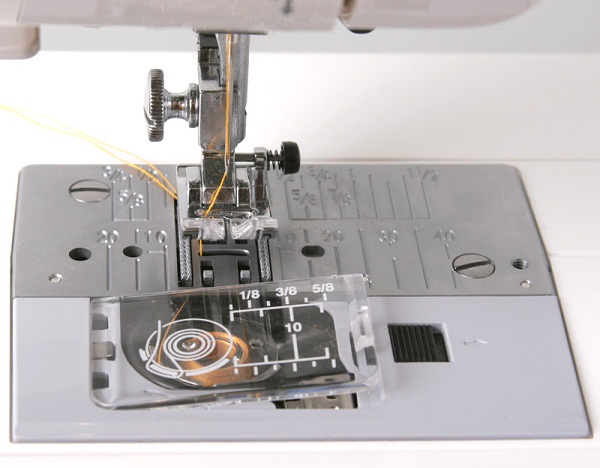

Horizontal view

Professional and semi-professional sewing machines are equipped with such devices. They have several advantages over other types:

- Perform more operations.

- Work with less noise.

- Have a great speed.

- They have a large margin of safety.

- No adjustment of the bobbin thread tension is required.

The horizontal type of shuttle is most common in computer models of sewing machines. The disadvantage of this type is that they are made of plastic. Hence the requirement to be careful when working on machines with a horizontal working axis. In case of failure, the horizontal mechanism made of plastic is more difficult to replace than the metal one.

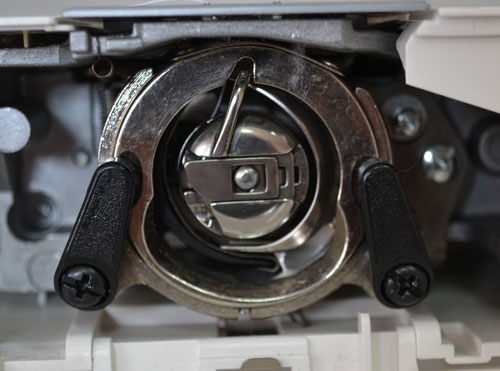

Shuttles of the vertical type

Are established on industrial cars and in expensive models of amateur sector. They are distinguished by good wear-resistant characteristics, as they are made of metal. Work at high speeds, smoothly perform their functions. They have several names that explain their type of labor movement:

- Double-skinned.

- Rotational.

- Rotating

The name double-hook shuttle is a professional expression used among masters. In order to make 1 stitch, the mechanism needs to turn twice. The thread is removed from the needle after 1 revolution, is threaded into the loop after the second. This is a professional level of work that is not used in everyday life. Suture loops are characterized by increased strength, there is no sagging threads. Such models easily cope with all types of fabric.

Rotary mechanisms rotate in the same plane as the working shaft of the sewing machine. This is the most commonly used model in the clothing industry. A distinctive feature is the very high speed of operations.

Rotating shuttles counterclockwise. This is the main difference from the pendulum models, which can also be attributed to the vertical type of arrangement of the mechanism. Unlike pendulum ones, they are used in industrial and semi-industrial sewing machines. Rotating models withstand large loads, from which the pendulum breaks.

But this type has a significant drawback - it requires frequent lubrication. If the procedure is untimely, the parts may fail, ruin the line.

Another drawback of vertical shuttles is their high cost.

How to make the right choice

In order to determine which shuttle is better to buy a machine with, it is necessary to precisely decide what types of work will be performed. For a limited range, quite inexpensive equipment with a pendulum working mechanism is quite enough. Novice seamstresses and users "from time to time" will cope with such a machine.

For workers in workshops, ateliers, vertical options are appropriate. They are reliable, hardy, have high speed, unpretentious with proper maintenance.

Horizontal types of shuttles in sewing machines are suitable for mass tailoring of products. These are quiet, high speed units. They have a large list of operations performed, not difficult to operate. Modern computers (machines) operate on horizontal shuttles. Household types of such equipment do not significantly differ in cost from electromechanical ones. At the same time, they are able to perform a much larger number of operations than models with a swinging look. Such a machine is needed for large volumes of tailoring.

An unequivocal answer to the question of which shuttle in a sewing machine is better to prefer - vertical or horizontal, does not exist. Too many nuances need to be considered when making the final choice. Consumers independently decide which shuttle to buy a car based on the specific situation.