3D printer is rapidly growing in popularity among modern buyers seeking to acquire advanced equipment for home use. However, not everyone understands how functional the device in question can be. The following article answers the most common questions related to the 3D device, in particular, what it generally represents, how and which 3D printer is best to choose for operation at home.

3D printer is rapidly growing in popularity among modern buyers seeking to acquire advanced equipment for home use. However, not everyone understands how functional the device in question can be. The following article answers the most common questions related to the 3D device, in particular, what it generally represents, how and which 3D printer is best to choose for operation at home.

Content

About product

The story of volumetric printing tools began in 1984, when Charles Hull, the then-famous company, first realized the idea of 3D printing using digital data.

A modern device for creating three-dimensional models forms a material object according to a computer model. Having saved the necessary item in the STL file format, the system transfers the created set of digital codes directly to the printer device itself. It, in turn, implements the created “drawing” into a familiar object with several sides, faces, corners and so on.

Traditionally, the process of three-dimensional printing is a series of cyclic actions consisting in “applying” a layer of consumables to the working surface of the printer, followed by shifting the table down to a level equal to the applied layer. In parallel with the change in elevator position, the 3D device mechanism removes “excess” material from the table. Then the cycles are repeated until the model is completely recreated in reality.

According to the technology of three-dimensional printing 3D printers are divided into types:

- FDM, using a nozzle-dispenser for “extrusion” and subsequent “superimposition” of layers of working material on each other (printers used in medicine, cooking, and so on);

- Polyjet, which implies "shooting" scanty doses of photopolymer through narrow nozzles and their subsequent instant polymerization, due to the action of a powerful ultraviolet ray (printers used in medicine or for industrial purposes);

- LENS, which are based on the result of the interaction of a working material, “blown” through thin nozzles, and a laser beam that instantly “bakes” the substance falling into its focus, giving it a holistic appearance of a three-dimensional part (traditionally used in large-scale industry);

- LOMs, which are laying thin layers of “working” material, cut with a knife or laser, on top of each other, followed by “pressing” and “baking” with ultrasonic vibrations (most often this type of printer is used in paper, aluminum or plastic) ;

- SL, the principle of which is "solidification" of the liquid polymer under the influence of ultraviolet radiation, which is activated after the "contouring" of the object's contours with a moving laser beam, followed by moving the elevator to create the next layer necessary for the implementation of the figure;

- LS, functioning similarly to the previous type of printers, but using a special powder instead of photopolymer, on the "hardening" of which the principle of operation of SL - devices is based;

- 3DP, creating objects that look like gypsum products by gluing powder layers of the "working" material used in the production of the future real object.

How to choose

Having an idea of the principle of operation and varieties of the printer for three-dimensional printing, the user will probably wonder how to choose the right gadget for home use.

The modern consumer market offers a wide range of models of printing devices with a large number of functions.For the purpose of a reasonable investment of finances in the purchase of really high-quality equipment, we recommend paying attention to a number of basic technical indicators, in particular:

- volume printing technology (for home use, the best choice will be FDM - a device that has an advantage in the cheapness of the "workflow" in comparison with its counterparts);

- printer design (the best option for purchase is a closed type of equipment that provides high printing speed, as well as the simplicity of setting up a "work" process);

- the diameter of the working nozzle and the possibility of replacing it (the vast majority of 3D printers are supplied by manufacturers with standard functional nozzles with a diameter of 0.4 mm, optimal for performing basic functions, and the possibility of their subsequent replacement if necessary);

- thickness of the print layer (the choice should be made in favor of a gadget with the considered indicator of 0.5 - 2 mm, providing high accuracy of printing "at the exit");

- The main computer software that regulates the printing process of a three-dimensional object (Cura is considered the most popular and proven software, the choice in favor of which is most appropriate for a potential user to use 3D devices by analyzing the presented range of equipment);

- printing speed (100 - 150 mm / s is considered the most optimal indicator of the printer's printing speed for home-creating a three-dimensional object).

Having studied the main features of the choice of the type of equipment under consideration, it is advisable for a potential user of a 3D device to pay attention to the following overview of the technical characteristics of the top printers of this segment, included in the rating of the best gadgets of 2019.

The best models

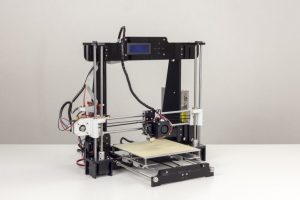

Anet a8

- Number of functional nozzle: 1

- Nozzle Diameter: 0.4mm

- Maximum thickness of the used material: 0.1 - 0.3 mm

- Print speed: 100mm / s

- Print Layer Thickness: 1.75 mm

- Voltage: 120 V

- Main Unit Software: Cura, Repetier-Host

- Supported formats: G-code, OBJ, STL

- Two-axis positioning accuracy: 0.012 mm

- Vertical Positioning Accuracy: 0.004mm

- Additional options: the ability to use an SD memory card

- reasonable price in comparison with similar products of the considered segment

- simple printer usage algorithm, understandable even for a novice user

- high print speed

- incomprehensibly formulated by the manufacturer instructions for using the gadget

- build quality of the overall design and individual functional parts

- low degree of safety of use

A low-cost 3D printer, ideal for use at home and in small businesses, thanks to its compact design and the acceptable price declared by the suppliers with print quality not inferior to the expensive technology of the segment in question.

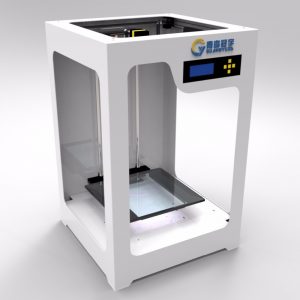

Creality3D CR

- Number of functional nozzle: 1

- Nozzle diameter: 0.4 mm (included replacement tips 0.2 and 0.3 mm in size)

- Maximum thickness of the used material: 0.1 - 0.3 mm

- Print speed: 150mm / s

- Print Layer Thickness: 1.75 mm

- Voltage: 150 V

- Main Unit Software: Cura

- Maximum nozzle heating temperature: up to 270 degrees

- Supported formats: G-code, JPG, OBJ, STL

- Weight: 130,000 kg

- Additional options: the ability to use an SD memory card; built-in functional LCD

- high print quality

- relative simplicity of assembly

- modern appearance of the device

- the need to install the printer on an exceptionally flat surface

- the high cost of "consumables"

- case material quality

A high-quality printer for volume printing, which differs from low-cost counterparts in high printing speed and the presence of a functional LCD display, greatly simplifying the operation of the printed gadget for the user.

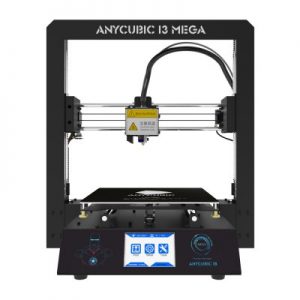

Anycubic I3 MEGA

- Number of functional nozzle: 1

- Nozzle Diameter: 0.4mm

- Maximum thickness of the used material: 0.05 - 0.3 mm

- Print Speed: 20 - 100 mm / s

- Print Layer Thickness: 1.75 mm

- Voltage: 110/220 V

- Main Unit Software: Cura

- Maximum nozzle heating temperature: up to 260 degrees

- Supported Formats: AMF, DAE, G-code, OBJ, STL

- Weight: 145,000 kg

- Additional options: the ability to use an SD memory card; built-in functional LCD

- clearly written user manual

- fast print speed

- build quality

- high degree of heating of the surface on which the printer is installed

- the need to purchase spare parts for the printer "to order"

- periodic malfunctions of unknown origin in the correct functioning of the device

A reliable 3D printer offered by suppliers at an average, affordable price will provide its user with high-quality fast printing at a low level of energy consumption.

Tevo Tarantula 3D Printer Kit

- Number of functional nozzle: 1

- Functional nozzle diameter: 0.4 mm

- Maximum thickness of the used material: 0.05 - 0.4 mm

- Print speed: 150mm / s

- Print Layer Thickness: 1.75 mm

- Voltage: 110/220 V

- Main Unit Software: Cura

- Maximum nozzle heating temperature: up to 260 degrees

- Supported formats: G-code, STL

- Two-axis positioning accuracy: 0.012 mm

- Vertical Positioning Accuracy: 0.004mm

- Additional options: the ability to use an SD memory card; built-in functional LCD

- "Extended" equipment, which implies the presence of replaceable parts

- simplicity of assembly

- quality of material used in the production of functional elements

- uneven work surface from the manufacturer, designed to install a functional design on it

- low level of actual heating of the nozzle, insufficient to work with some materials, in particular nylon

- Inconsistency of accuracy indicators of positioning "in practice" with the characteristics specified by the manufacturer

Inexpensive device for volume printing, which is in great demand among customers and best demonstrates its functionality in home use, due to various types of compatible formats and ease of assembly of its design.

Before directly buying a 3D printer, a potential user needs to make sure that they have a clear idea of what kind of device it is and what technical characteristics it should have. Having carefully studied the above information, it will not be difficult for the buyer to choose a really high-quality device that meets the basic requirements for the technology of its segment.

Materiel must be taught, guys, before you advise anything!

you have: Print layer thickness: 1.75 mm. In fact, 1.75 mm is the diameter of the bar used to print. And why did you get the idea that Creality has “the high cost of consumables” (quote), while ANET, using the SAME BAR, is everything OK?

It caught my eye right away. A man who was far from print wrote

So which printer do you recommend for a home within 30,000 rubles?