Cement mortar preparation is an integral part in construction work. Mixing it in large quantities is quite difficult, and also requires a lot of time and effort. A puncher or a powerful electric drill is well suited for this. You should not rush to rent, let alone buy a concrete mixer or a construction mixer. In most cases, this is completely inappropriate.

Is kneading with any tool allowed?

It is important to understand that the weaker the power tool, the harder it will work. If we are talking about the use of a drill, then it should be borne in mind that not every model is designed for this kind of load. For example, a 500 W device is not capable of fully kneading a building mixture. With intensive work, the drill motor will definitely fail. With this tool, you can mix the solution only in very small volumes (about 10 l) and for a short time. It is also important that it was not thick concrete, but putty, primer, or the like.

A completely different thing is an electric drill with a powerful motor of 1300 watts, better than 1500 watts. A similar model may well cope with the mixing of mortar. However, all the same, one should not overload the tool with increased intensity of work, and also try to knead too thick a mass.

As for the application for kneading with a puncher, this is a more reasonable solution. This tool is designed for increased loads and is equipped with a powerful power unit. Nevertheless, when mixing concrete, it is better to take frequent breaks in work.

How to mix the solution?

Regardless of the choice of tool, mixing the mortar should be from the most liquid consistency, to a thicker one. In other words, it is necessary to add cement and sand to the composition of one bag in order to achieve the necessary density in two, or better, three runs. If you try to immediately make a very dense solution, it will be quite difficult and will negatively affect the engine and the internal mechanism of the power tool.

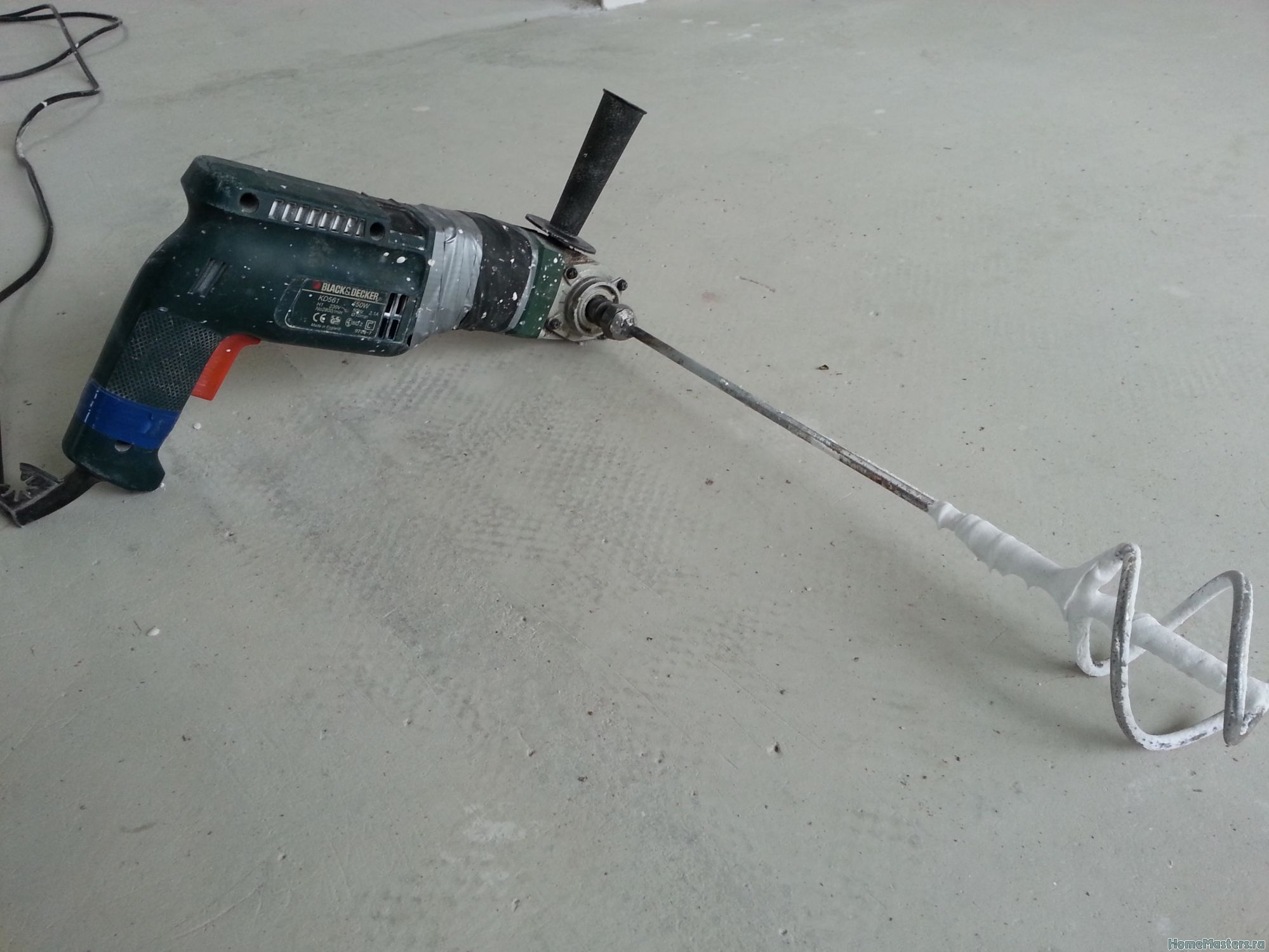

It is also important to choose the right nozzle. There are three types in the assortment of building stores:

- screw;

- cruciform;

- combined.

Screw mixers are used to produce liquid mixtures, and cruciform mixers for thicker ones. Cross-shaped nozzles with a right-handed spiral work well with a solution in the composition, which includes gravel or crushed stone. The nozzle evenly distributes the components throughout the volume, preventing them from falling to the bottom. Combined nozzles are a universal solution, and can be used in mixing any building mix.

To minimize the load on the drill, it is better to give preference to a mixer with the smallest possible size of the working part. The wider the mixer blades, the more power is required to rotate them under the load of the solution. A more impressive mixer can be purchased with a hammer drill than with a drill. Since this tool can work under heavy load and develops great power.

The effectiveness of this method

Many builders are very skeptical about this method of bags of mortar. And in fact, special devices were invented for this purpose - a concrete mixer and a construction mixer. If these devices are at hand, then it is better to use them. However, it makes no sense to purchase a construction mixer for periodic repairs. In such cases, most often you can do with a fairly powerful drill or punch.