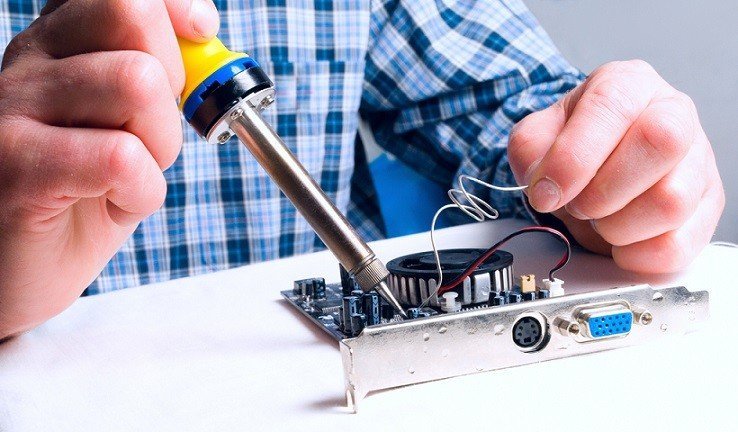

Almost every master in the household has such a useful tool as a soldering iron. But not everyone knows that using this tool can not only solder. There are small secrets to working with a soldering iron that can be useful to every master.

Content

How to solder a small part if the soldering iron tip is too thick

There are varieties of soldering tools whose tip is very thick. It would seem that they can not solder small parts, but this is not so. To do this, you need to slightly transform the sting.

Take a copper wire with 1 core up to 10 cm long. With a knife, remove the insulating layer from it, removing the varnish coating, using annealing or a sharp knife. After that, tightly wind the wire onto the tip of the soldering iron, having previously cleaned it of carbon with fine emery paper.

Bend the tip of the wire with pliers. The length of the new thin sting should not be too long. Otherwise, the sting will overheat, and it will be difficult to work with it.

Dispense components with a syringe needle

For soldering microcircuits, you do not need to purchase expensive tools or a new soldering iron. This can be done by adapting the existing soldering iron with a simple medical needle.

For convenience, the angle should be sharpened at an angle of 90 or 45 degrees. Before starting soldering, the needle must be put on the protruding nose of the chip, and then bring the soldering iron to the needle. After heating the solder, bring the soldering iron to the needle, gently turning it. In this case, the needle heats up and gradually enters the board, freeing the leg from solder.

Use pliers instead of a third hand

Almost everyone had a situation when they didn’t have enough hands when soldering. Pliers can be fitted for this.

To begin with, you should choose a strong and stable base, for example, a case from a table clock. Drill 3 holes in it for attaching flexible legs. Use tape to rewind the ends of the legs. Due to this, they can be simply, quickly and reliably fixed in the holes of the base.

Take 2 crocodiles and put thermal shrinkage on their metal teeth. This is necessary in order to prevent the possibility of damage to the working surface with metal teeth.

Glue crocodiles to the ends of the legs. Super glue can be used for this. Such a stand can be used to fasten wires, bulbs, stylus clamps, solder.

Cut a piece of complex shape out of glass using a soldering iron

In order to cut out a complex shape from glass, it is not always practical to use a glass cutter. A soldering iron and a file are excellent for this.

On the surface of the glass draw a contour of the future figure. Make a furrow of small depth near the edge of the figures with a file. Having departed from it 1.5 mm, heat the glass by using a soldering iron. Do not stop heating until the glass gives a small crack.

Repeat such actions until all glass contours are separated from the main piece. In order for the cut line to be perfectly smooth, it is recommended to use a metal ruler, near which the glass is heated.

Plastic cutting with a soldering iron

Using a soldering iron, you can quickly and easily cut the plastic. To do this, take the copper wire and remove insulation from it. Then hammer the wire.Thanks to this, it will become almost smooth. The length of the wire should be within 2-3 cm.

Having departed from one edge of the wire 1 cm, make a hole in it. A hacksaw for working on metal just below the hole to perform a cut in the wire. For the convenience of this operation, it is recommended to use a vise.

Insert the knife blade into the finished cut, securing it with a small screw. Insert the device into the soldering iron tip and turn it on. Thus, a hot knife is ready with which you can cut plastic.

The soldering iron can be used not only for soldering, but also for cutting plastic and glass, soldering microcircuits. It is enough to modify the tool a little and apply imagination.

DO NOT pick up the soldering iron !!!

.. ”The length of the new thin sting should not be too long. Otherwise, the sting will overheat, and it will be difficult to work with it. ”- What does this mean, the longer the thin sting of wire, the hotter it will be?

About soldering microcircuit legs with a needle is generally absurd. While you heated one, took on the next, what will happen to the previous one? All legs are heated at the same time, being in the same row! Why publish tips if you yourself have no idea about this ?!

Valerych, what confused you with the soldering needle? This is a working method for working with DIP housings and why is it such a statement that the legs on one side are heated together? Do you even study the structure of microcircuits before the start of the upstart. The author for beginners apparently prepared the material. You are not a beginner, you are just a teapot in this at all. A long sting will not overheat at the tip and will bend, and soldering will also be impossible, and this is not convenient. Although here I have to disagree with the author’s methodology. The master with any sting and 0805 and 0603 of the case freely solders and solders. This is a matter of experience. A wound wire kanechno nonsense. The master should have replaceable stings, if it is difficult to work alone.

Well and of course I am an opponent of rosin when working with small smd, especially when the accuracy is high. Many fill and do not wipe the marking of cuts and no tracks are visible. Solder the roasting pot please. In general, nothing, but much better.

I have our Soviet soldering iron, I don’t even know how old he is, I usually solder the parts 0805 to them. Try soldering with wire it is completely nonsense. Cut plastic with a soldering iron and breathing this muck is an amateur.